Rigid & Stable Structure Design

The optimal solution for high-speed and high-precision machining of large-size workpiece

1. X/Y 軸多線軌及大跨距機台設計結構 。

2. 三軸滾柱型線軌: 達到高精度、重負荷等特性,相較滾珠線軌提升 20% 整機剛性 。

3. Z 軸四線軌三面拘束結構專利技術: 雙向支撐提供高剛性,為您的切銷帶來絕佳的剛性表現。

Logout?

Are you sure to log out ?

Return

Gantry type 5-axis machining center

High Speed High Precision Gantry type 5-axis machining center

High Efficiency Solutions for Aerospace Components

One & only :

1. X/Y 軸多線軌及大跨距機台設計結構 。

2. 三軸滾柱型線軌: 達到高精度、重負荷等特性,相較滾珠線軌提升 20% 整機剛性 。

3. Z 軸四線軌三面拘束結構專利技術: 雙向支撐提供高剛性,為您的切銷帶來絕佳的剛性表現。

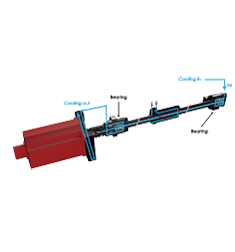

Twin ballscrew design on Z axis

Thermal growth control on Z axis

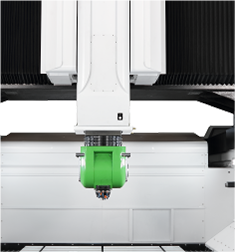

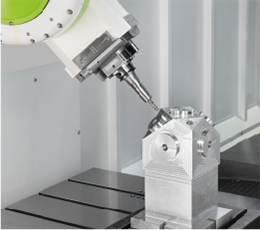

CYTEC 5 axis head

1. Twin ballscrew design on Z axis.

2. Thermal growth control on Z axis: Motor base, ballscrew, nuts and bearings are completely cooled, which increases dynamic rigidity and axis accuracy by 15%.

3. Assembly with Germany made Cytec 5 axis head delivers high precision.

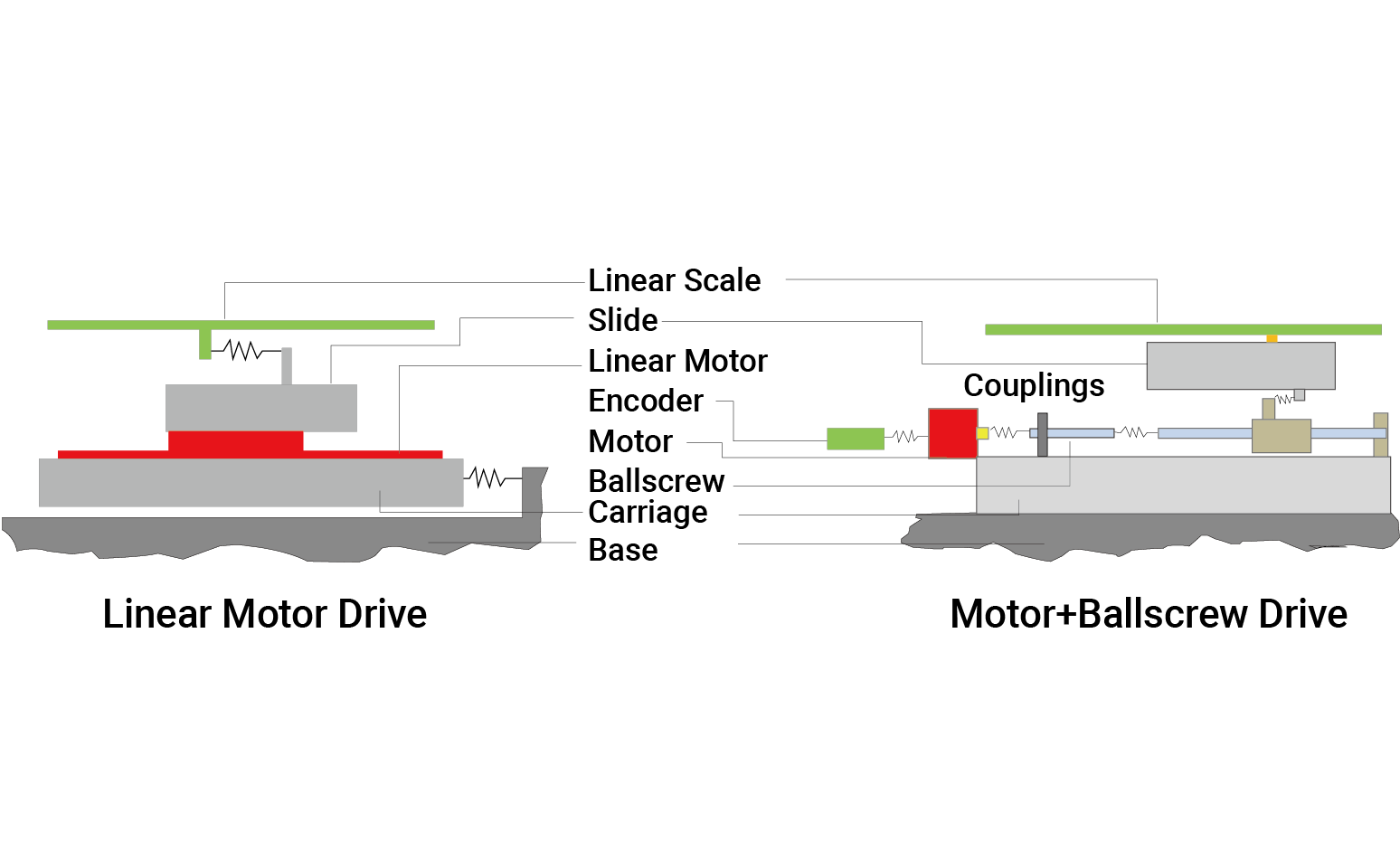

Linear motor

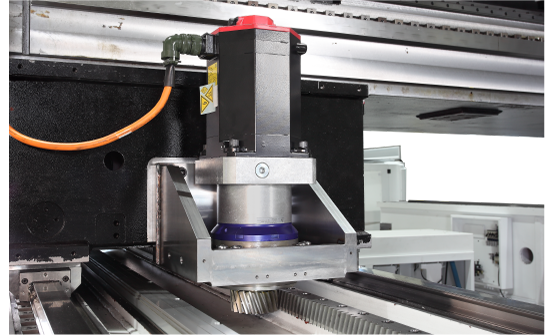

Rack and pinion on X axis

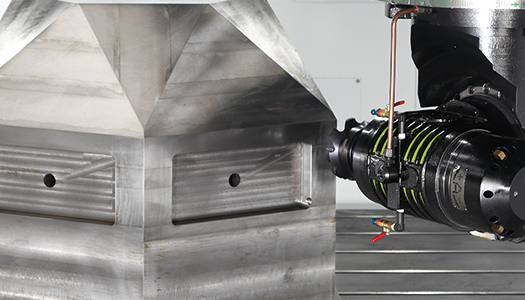

1. Linear motor: Achieve the best advantages of high processing efficiency and high precision effectively.

九面體

S CUT

1. Decades of machine tool manufacturing technology, plus new developed AI technology, makes the machining accuracy/efficiency/finish almost equal to the level of Japanese machines

2. “Super Speed Cycle time” makes cutting efficiency 15% ~ 50% higher than Taiwanese peers.

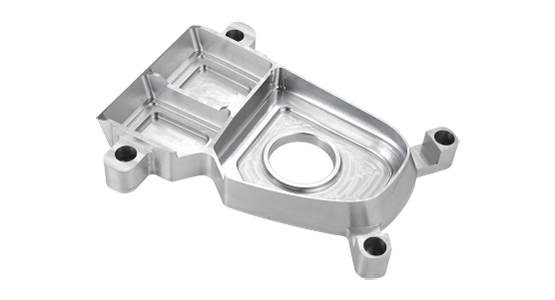

.Model:Aero-632/ 5X

.Spindle:HSK-A63 Built-in 24,000 RPM 43 KW

.Cutting material:Aluminum die cast ADC12

Tolerance of 3D contouring accuracy conforms to the standard:

Result of 114 spots test is approved within tolerance (± 0.02mm).

OMV (On Machine Verification): 3D Inspection is directly employed based on OMV system, which ensures each workpiece is qualified, and efficiency is enhanced to reduce time on workpiece upload/load on the table.

Worktable size

6000 x 2700

mm

Max. load (Average)

5000kg / 每平方米

kg/ m2

X axis travel

6000

mm

Y axis travel

3200

mm

Z axis travel

1100 (1300 opt)

mm

Spindle nose taper

HSK-A63 / HSK-A100

Spindle (Built-in)

24000 (HSK-A63)

rpm

Spindle (Built-in)

12000 ( HSK - A100 )

rpm

Capacity

S type 30 (opt 40), A type 40 (opt 60)

pcs

Spindle drive motor (Cont. / 30 min)

37 ( HSK-A63 ) / 43 ( HSK-A100 )

kw